E.P machinery company Mini Digger, Mini Excavator Factory

Mini excavators may seem small and powerful, but they often work in harsh environments. The surrounding dust and muddy roads will more or less affect your machine. Want to know the most vulnerable parts of a mini excavator? Don’t worry, pleas follow me one by one.

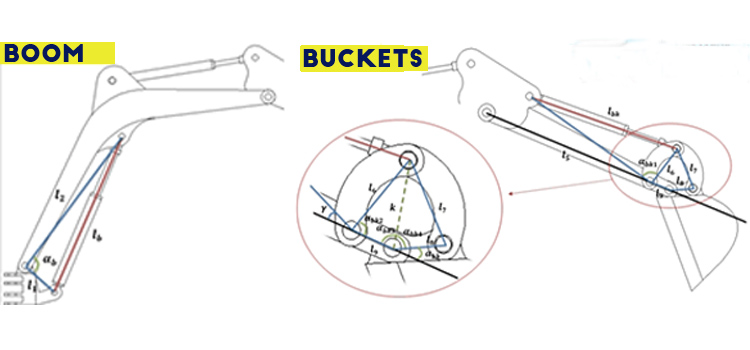

The main function of a mini excavator is excavation, but sometimes it can also be "qualified" for other tasks, for example they can be used to drill piles and lay pipes depending on the work requirements. After performing these high-intensity work for a long time, the bucket cylinder connecting pin and bushing may become loose or even fall off. Many failures are caused by neglect of maintenance and inspection of these key parts, so you need to check them regularly to ensure there is no problem with the working device during pile driving and crushing.

In addition, you also need to carefully check the place where the rear arm is connected to the excavator. This place may be subject to varying degrees of wear during work.

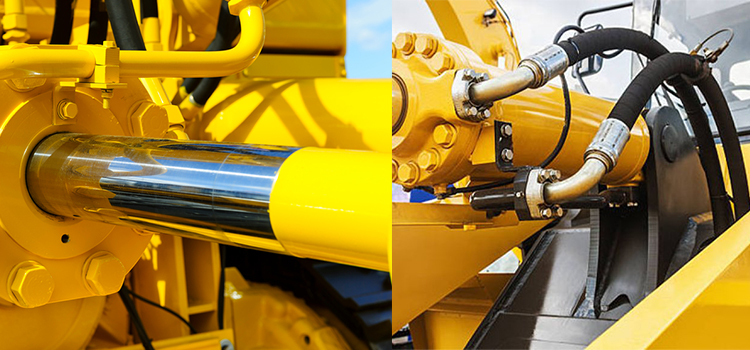

The surface of the hydraulic cylinder and oil pipes is easily scratched or directly scratched and dented after using a small excavator for a long time. In severe cases, oil may even leak. Therefore, it is necessary to regularly check whether the cylinder wall is damaged. The gap between the cylinder and cylinder wall is very small. If debris remains in the pipe, it will wear the cylinder, and the debris may also cause damage to the hydraulic system.

The excavator is suitable for walking on various terrains, whether it is muddy land or mountains, so this part is also easy to be worn, especially the edge part of the crawler track, which is often severely worn. The working life of the crawler track is generally about 2,000 hours, but if it works in a harsh environment with rocks, the life span will be shortened by about 500 hours. Therefore, if the project environment is very poor, it is best to choose steel crawler tracks and pay attention to maintenance.

Pay attention to the maintenance of the above "vulnerable" points. The service life of the E.P Machinery mini. Excavator can be extended for at least several years, and the maintenance cycle must be completed on time so that it can stay with you longer.