E.P machinery company Mini Digger, Mini Excavator Factory

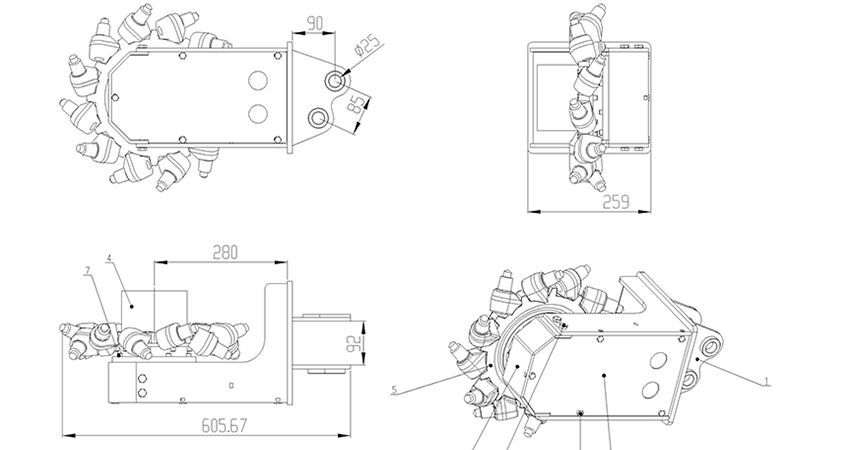

Milling Head Structural diagram

Milling Head, also known as the milling and digging head, is an auxiliary tool for the excavation and repair of mines, tunnels, diversion culverts, subways, and other areas. It can be installed on any powered hydraulic machinery such as excavators and slag raking machines to achieve excavation and repair operations. It is an efficient alternative to general equipment such as digging buckets, crushing hammers, and hydraulic shears, and is used for tunnel excavation and contour correction. During the excavation process, there is low disturbance to the strata, small noise, and high safety of excavation, making it particularly suitable for areas that are not suitable for blasting construction.

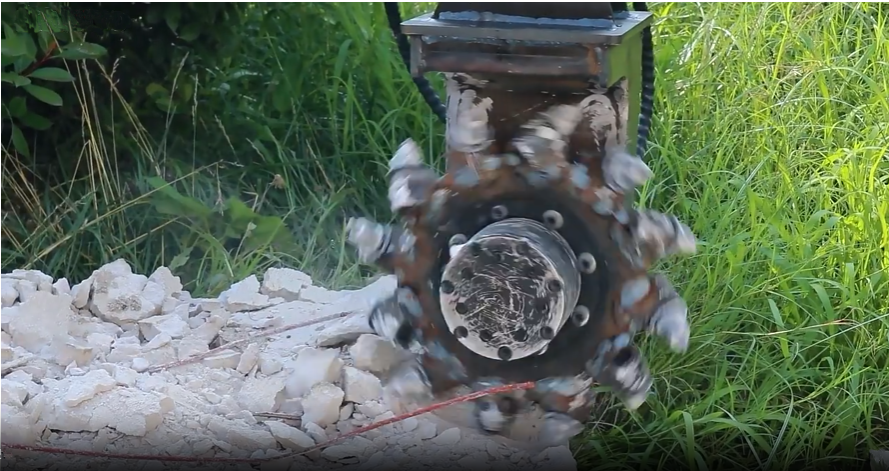

Milling Head is installed on a small excavator

Milling Head are specialized in various purposes such as excavation, slotting, brushing, and trimming. They are used in conjunction with excavators to achieve various purposes such as milling, excavation, loading, and transportation. They are suitable for various underground mining operations, especially for small tunnels in coal mines. They have fast excavation speed, safety, low energy consumption, low consumption, and one-time forming.

Install a small excavator with a milling excavator to break the stone slab and ground

In addition, the milling machine is significantly effective in demolishing buildings by milling and excavating foundations, concrete slabs, and thick concrete walls with minimal steel reinforcement. It can achieve the dual functions of hydraulic crushing hammer and hydraulic pliers, as it can simultaneously mill and break steel bars in buildings; The material excavated by milling has a small particle size and can be directly used as backfill.

The milling machine is demolishing buildings

Main hydraulic safety valve、 Heavy duty seals and bearings、 Simple oil circuit design、 Direct drive by low-speed high torque motor、 Protecting the environment、 Low noise and vibration、High torque output、 No oil drain pipe

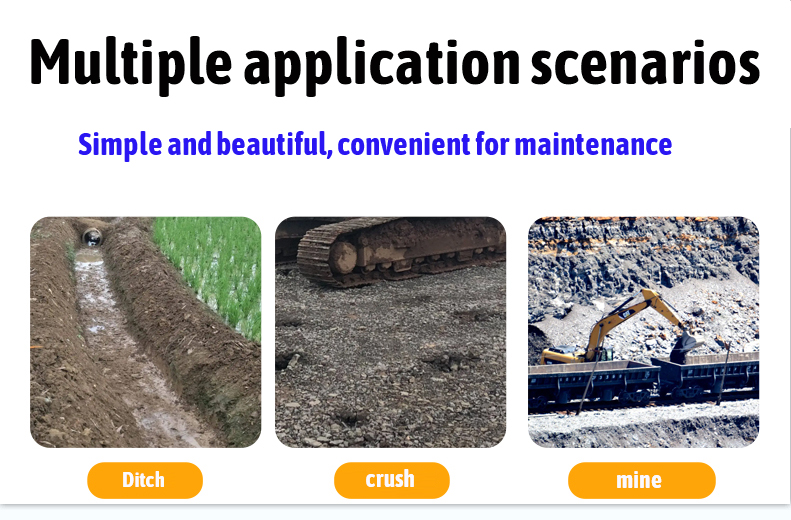

Capable of precise shaping of ditches、tunnels、 and surfaces、Less harm to surrounding buildings、Suitable for large-scale applications、 Milling and excavation materials can directly backfill the working range、 Mining、Tunnel engineering、 Water conservancy and hydropower、 River channel trimming、 Trench excavation、 Removal of obstacles、 Slope trimming、 Frozen soil construction、 Shaft sinking

Maximum Output Torque:1500NM

Maximum Working Pressure:21Mpa

Maximum Flow:20 liters/minute

Motor Form:Piston Motor

Suitable for excavators:0.8T——50T